Comparison of PVC floor and rubber floor

1. Briefly describe the comparison between PVC floor and rubber floor?

The composition and production process are different: The rubber floor is divided into homogeneous and heterogeneous. PVC flooring such as homes, hospitals, schools, office buildings, factories, public places, supermarkets, commerce, and other places. "PVC floor" refers to the floor made of polyvinyl chloride materials. The main component of the plastic floor manufacturer is polyvinyl chloride material. PVC floor can be made into two kinds, one is homogeneous and transparent, that is, the pattern material from the bottom to the surface is the same. Stone plastic floor is a new type of floor decoration material developed by high-quality, high-tech research and development. It uses natural marble powder to form a solid base layer with high density and high fiber network structure, and the surface is covered with super wear-resistant polymer PVC. Layers are processed through hundreds of procedures. Homogeneous rubber flooring is based on natural rubber or synthetic rubber, with a single-layer or multi-layer structure of the same color and composition. Heterogeneous rubber flooring is based on natural rubber or synthetic rubber.

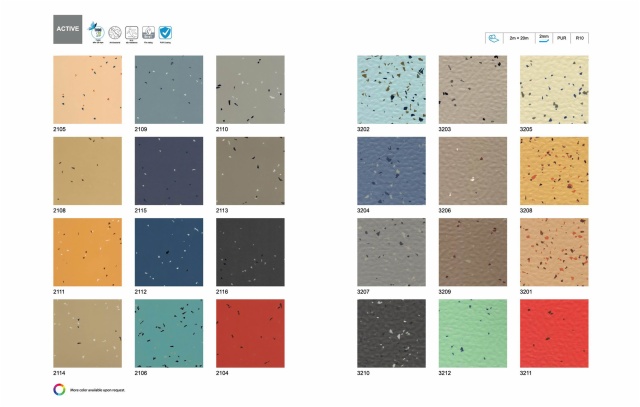

Color difference: Color rubber floor is more difficult, because rubber has a strong absorption color, which is relatively single most colored rubber floor; PVC floor and color are very many, any combination, can provide designers with more choices.

The difficulty of installation is different in different degrees: the PVC floor is light in texture, which is convenient and quick to install and use; the rubber floor is heavy, and it is more laborious to install one. Moreover, the installation method of the rubber floor can require students to be more strict. If the teaching method is wrong, bubbles will appear, and the requirements for the self-leveling foundation will be more perfect, otherwise the defects of the base will be exaggerated.

Market demand and poor wear resistance: Due to the high price of rubber flooring, it is only used in some high-end places, such as hospitals, high-speed railways, power stations, aircraft boarding bridges, stations and other places. Used in a narrower range; and PVC flooring is widely used due to its high cost, and the market potential is huge. Also wear rubber flooring, the stronger it is, it is suitable for a large number of airports, stations and other high-traffic sites, as well as planes, trains, subways, cars, boats and other vehicles.

2. Quality management requirements for PVC flooring products

2.1. The temperature of the indoor space environment when glue is applied must be greater than 10°C, otherwise construction is prohibited. When the temperature is above 10°C, the glue drying treatment time is determined according to the specific working temperature of the company.

2.2, all applicators must be applied, and at the same time spread evenly.

2.3, and reasonable uniform cutting.

2.4. The slotting speed develops evenly and straight, and the slotting has no burrs.

2.5. Clean the excess glue or other debris in the welding tank before welding.

2.6. The welding line is stable and the line is straight.

2.7. The first removal of excess welding rod must wait until the temperature of the welding rod is slightly lower before proceeding.

2.8. During the laying of PVC floor board coils, students must be able to maintain a clean, closed, weather-proof, and maintain a certain temperature in the enterprise for at least 48 hours before and after the students.

2.9. The relative humidity of the indoor environment shall not exceed 60%. The technical conditions for storage of materials are the same.

2.10. Roll up and down the PVC floor and put labels on it. Make sure that the color, volume, and batch number are clearly marked.

2.11. If multiple rolls of the same product color material are used, and the same production batch number must be used, they should be laid in the order of the roll number. Use multiple batches of materials, and be careful not to put different batches of materials in parallel for development and laying.

2.12. The materials should always be arranged in alternating directions to avoid chromatic aberrations at the stitches.